Enhanced Traffic Line Paint Solutions: Tailoring Thermoplastic Markings for Road Safety

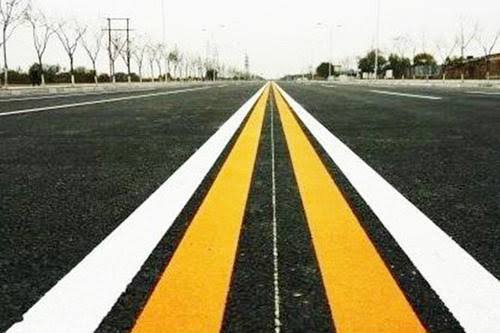

In the quest for safer roads, the significance of high-quality traffic line paint cannot be overstated. These markings guide millions of drivers daily, helping to reduce accidents and enhance the overall flow of traffic. Among the various solutions available, thermoplastic traffic line paint stands out for its durability, visibility, and long-term cost-effectiveness. This article delves into the intricacies of thermoplastic traffic line paint, exploring its benefits, application processes, and the latest advancements that are setting new standards in road safety.

The Importance of Quality Traffic Markings

Traffic markings play a pivotal role in road safety, offering guidance and information to drivers and pedestrians alike. They delineate lanes, indicate pedestrian crossings, signal directions for turning, and provide other crucial information. The quality of these markings directly impacts their visibility and durability, influencing the overall safety and efficiency of road transportation.

Thermoplastic Traffic Line Paint: An Overview

Thermoplastic traffic line paint, a material composed of synthetic resin, glass beads, pigments, and fillers, is known for its superior longevity and reflectivity. Unlike traditional paints, thermoplastic markings are applied hot and cool down to form a bond with the pavement, resulting in a thicker, more durable line.

Key Benefits

• Durability: Thermoplastic markings can last up to six times longer than conventional paints, resisting wear and tear from heavy traffic and adverse weather conditions.

• Visibility: Enhanced with reflective glass beads, these markings remain highly visible at night or during rain, significantly improving road safety.

• Eco-Friendly: Thermoplastic paints emit lower levels of volatile organic compounds (VOCs), making them a more environmentally friendly choice.

• Cost-Effectiveness: Although the initial cost is higher, the long lifespan of thermoplastic markings makes them more cost-effective over time.

Application Techniques

The application of thermoplastic traffic line paint requires specialized equipment and expertise. The process involves heating the thermoplastic material to a specific temperature before it is applied to the road surface. There are two primary methods:

• Preformed Thermoplastic: Pre-cut into various shapes and symbols, this method involves heating both the pavement and the thermoplastic material before pressing it onto the surface.

• Screed Application: This method involves pouring the heated thermoplastic material directly onto the pavement, where it is then spread into lines using a screed box.

Both methods require the road surface to be clean and dry, ensuring the thermoplastic material bonds effectively for long-lasting results.

Innovations in Traffic Line Paint

The field of traffic line paint is witnessing continuous innovation, with research focused on improving the durability, reflectivity, and environmental sustainability of these markings. Recent advancements include:

• Eco-Friendly Formulas: Newer thermoplastic materials are being developed with bio-based resins and recycled glass beads, reducing the environmental impact.

• Improved Reflectivity: Advances in glass bead technology have led to beads that maintain their reflectivity longer, ensuring markings are visible even under less ideal conditions.

• Temperature-Adaptive Materials: Innovations in material composition allow thermoplastic paint to adapt to temperature changes, reducing cracking in colder climates and softening in extreme heat.

Challenges and Solutions

While thermoplastic traffic line paint offers numerous benefits, there are challenges in its application and maintenance. These include the need for specialized equipment, sensitivity to weather conditions during application, and the risk of skidding on freshly applied markings. Addressing these challenges requires ongoing training for application crews, investment in high-quality application equipment, and research into materials that can reduce skidding risks.

Regulatory Considerations and Standards

The application of traffic line paint is subject to regulatory standards and guidelines, ensuring consistency and safety across road networks. These regulations cover aspects such as the thickness of the markings, the size and placement of symbols, and the reflectivity levels required. Compliance with these standards is crucial for maximizing the effectiveness of traffic markings in enhancing road safety.

The Future of Road Markings

Looking ahead, the future of road markings is set to be shaped by technological advancements and a growing emphasis on sustainability. Smart road markings, capable of changing color or pattern in response to traffic conditions or weather, are under development. Similarly, the integration of thermoplastic markings with autonomous vehicle technologies is being explored, with the potential to significantly enhance the interaction between self-driving cars and road infrastructure.

Conclusion

Thermoplastic traffic line paint is at the forefront of efforts to enhance road safety through high-quality, durable, and visible markings. As we have seen, this solution offers numerous benefits over traditional paints, from improved durability and visibility to environmental sustainability. However, the full potential of these advancements depends on addressing the existing challenges, adhering to regulatory standards, and continuing to innovate. By doing so, we can ensure that our roads remain safe, efficient, and adaptable to the demands of modern transportation.